In the realm of fuel transport and storage, a fuel bowser plays a critical role in delivering fuel to remote locations, construction sites, agricultural fields, airports, and even military operations. Understanding the capacity of a fuel bowser is essential for logistics, cost calculation, and ensuring safety during fuel handling. In this article, we will delve into what a fuel bowser is, explore the various capacities available, and discuss the factors that influence its design and usage.

Understanding the Fuel Bowser

A fuel bowser, also known as a fuel tanker, is a mobile tank designed to store and transport liquid fuel such as diesel, petrol (gasoline), aviation fuel, or kerosene. These units can be mounted on trucks, trailers, or even towed units, depending on their size and purpose. They are used in sectors where stationary fuel storage is not feasible, or where on-site refueling increases operational efficiency.

Fuel bowsers are commonly seen in industries such as:

- Construction

- Mining

- Agriculture

- Aviation

- Emergency services

- Military logistics

Standard Capacities of Fuel Bowsers

Fuel bowsers come in a wide range of capacities, depending on their design, application, and country-specific regulations. Here are the general capacity ranges:

1. Small Capacity Bowsers (200 to 1000 liters)

These are compact units often mounted on trailers or skids. They are suitable for:

- Small construction sites

- Agricultural equipment refueling

- Emergency fuel supply

- Small-scale operations where maneuverability is key

Due to their small size, these bowsers can be towed by a pickup or a small tractor. They are often used for diesel and petrol.

2. Medium Capacity Bowsers (1,000 to 5,000 liters)

These are commonly mounted on 4×4 trucks or trailers and are widely used in:

- Medium-scale agricultural operations

- Commercial fuel delivery

- Fleet refueling

- Mining support

Medium bowsers strike a balance between capacity and mobility. They offer a good supply for daily operations without requiring heavy-duty transportation equipment.

3. Large Capacity Bowsers (5,000 to 20,000 liters)

Typically built on rigid trucks or semi-trailers, these are suited for:

- Large construction projects

- Remote site fuel delivery

- Highway and infrastructure projects

- Commercial fuel distribution

Such units usually come equipped with pumping systems, meters, hoses, and nozzles to facilitate fuel dispensing. They are ideal for bulk transportation of fuel.

4. Extra-Large Bowsers (20,000 to 50,000+ liters)

These are high-capacity tankers, often seen in logistics for fuel companies, airports, or military convoys. They are used to transport:

- Jet fuel (for aviation refueling)

- Diesel or petrol in bulk

- Fuel for remote or undeveloped regions

Mounted on articulated trailers (semi-trailers), these bowsers require special licensing and adherence to strict safety regulations due to their high capacity and the hazards involved in transporting large volumes of fuel.

Factors Influencing Fuel Bowser Capacity

Several factors determine the optimal capacity of a fuel bowser:

1. Purpose of Use

The end application plays a central role. For example, an airport refueler may require a 40,000-liter bowser, while a farm may only need 1,000 liters for tractors and harvesters.

2. Type of Fuel

Different fuels may have regulatory or safety considerations that limit how much can be carried at once. For instance, petrol is more volatile than diesel and may be subject to stricter volume restrictions during transport.

3. Vehicle or Trailer Configuration

The gross vehicle weight (GVW) and axle configuration influence how much weight (and hence, fuel) the vehicle can legally carry. A 3-axle trailer can support more load than a 2-axle one, making it suitable for high-capacity tanks.

4. Road Regulations and Licensing

In many countries, transportation authorities impose limits on fuel transportation, especially on public roads. Operators must also have specific licenses to transport hazardous materials. These regulations influence the bowser size.

5. Design and Materials

Fuel bowsers are made from materials like mild steel, stainless steel, or aluminum, each influencing weight and durability. Aluminum, for example, is lightweight, allowing more volume capacity within weight limits.

6. On-site Space and Accessibility

In confined construction or urban sites, a large fuel bowser may be impractical. Compact bowsers are better suited for maneuvering in tight spaces or rough terrain.

Common Fuel Bowser Configurations

Let’s look at typical configurations and their capacities:

| Configuration | Capacity Range | Notes |

|---|---|---|

| Towable Trailer Bowser | 200 – 3,000 L | Best for short-range, mobile refueling |

| Truck-Mounted Bowser | 3,000 – 15,000 L | Used for daily operations on large sites |

| Semi-Trailer Fuel Tanker | 20,000 – 50,000+ L | Ideal for long-distance or bulk delivery |

| Aircraft Refueler Bowser | 5,000 – 45,000 L | Specialized for aviation fuel with filtration systems |

Safety and Compliance

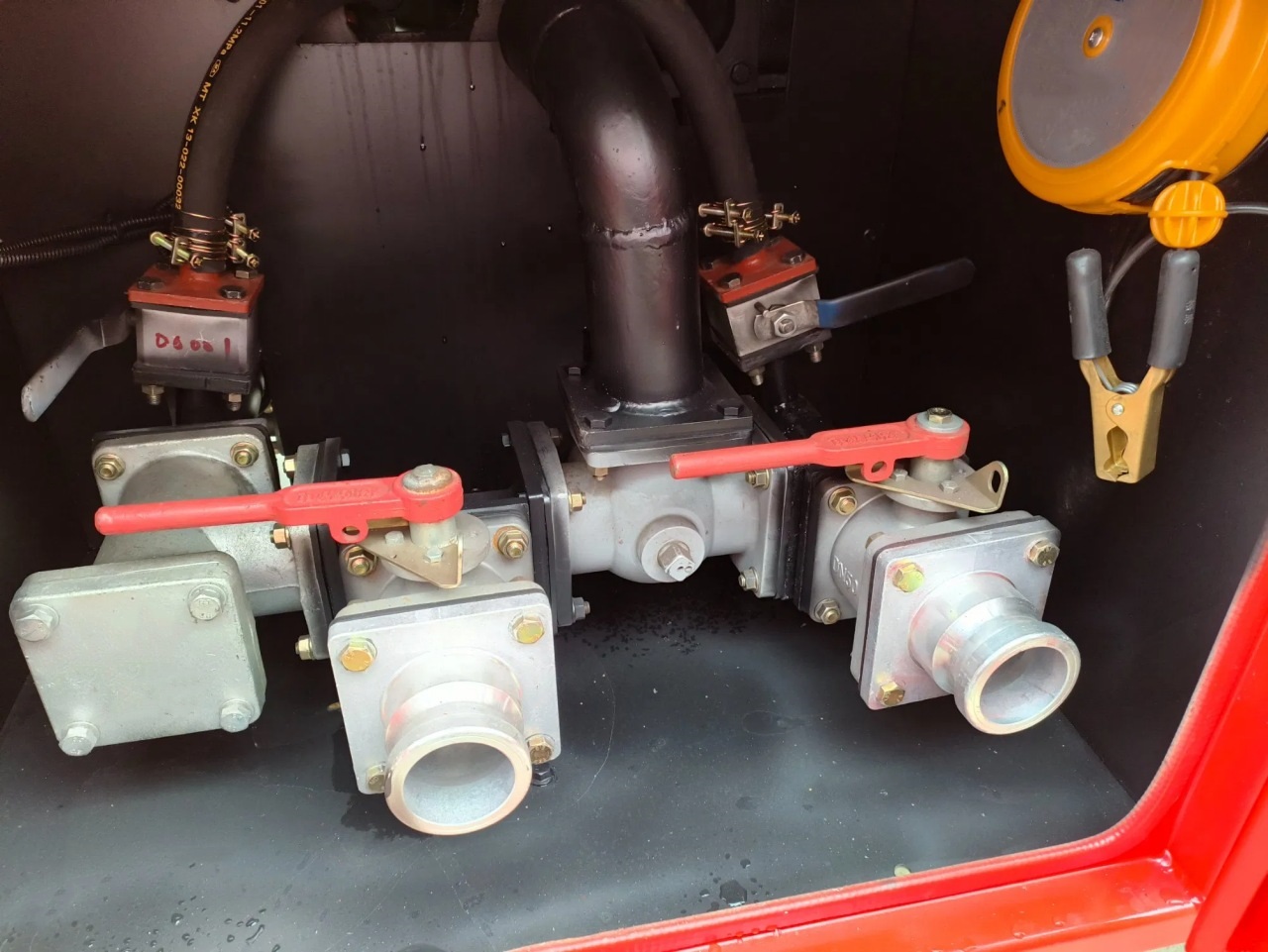

Fuel bowsers must meet national and international safety standards, especially when transporting flammable liquids. Safety equipment and features may include:

- Fire extinguishers

- Anti-static grounding systems

- Spill containment measures

- Lockable fill points and hatches

- Certified pressure testing

- Safety decals and emergency signage

Compliance with standards such as ADR (in Europe), DOT (in the USA), or ISO guidelines is often mandatory.

Conclusion

The capacity of a fuel bowser varies widely depending on its application, design, and regulatory environment. From compact 200-liter units to massive 50,000-liter semi-trailers, fuel bowsers are tailored to meet the diverse needs of industries that rely on mobile fuel supply. Understanding the appropriate bowser capacity ensures operational efficiency, cost-effectiveness, and most importantly, safety.

When selecting a fuel bowser, always consider your fuel volume needs, delivery frequency, transport limitations, and regulatory compliance. With the right capacity and configuration, a fuel bowser can become an indispensable tool in your fuel logistics operation.