In the world of logistics, construction, agriculture, and emergency services, the efficient and safe transportation of fuel is paramount. One of the most important tools that enable this is the fuel bowser. While it may not be a household term, fuel bowsers are critical to operations where mobility, reliability, and access to fuel are required in remote or off-grid locations. This article will explore what a fuel bowser is, its types, components, uses, safety considerations, and regulatory requirements.

Definition of a Fuel Bowser

A fuel bowser is a mobile tank system used to store and dispense fuel such as diesel, petrol, aviation fuel, or kerosene. Bowsers can be trailer-mounted, truck-mounted, or even skid-mounted for static applications. Their main purpose is to provide a mobile refueling solution for vehicles, machinery, aircraft, and generators in areas where a fixed fuel station is not available.

The term “bowser” originally comes from Sylvanus Bowser, who is often credited with inventing the first fuel pump in the early 20th century. Today, the term is commonly used in the UK, Australia, and some parts of Asia and Africa.

Types of Fuel Bowsers

Fuel bowsers come in various forms, each tailored to specific industries and operational environments. The main types include:

1. Trailer-Mounted Fuel Bowsers

These are towed behind vehicles and are commonly used in agriculture and construction. They offer easy maneuverability and can be quickly deployed to different sites.

2. Truck-Mounted Fuel Bowsers

These are permanent or semi-permanent tanks fitted onto truck chassis. They have larger fuel capacities and are used for bulk delivery and commercial refueling services.

3. Skid-Mounted Bowsers

These are non-mobile bowsers placed on skids or bases for stationary use. They are often used on industrial sites or remote locations for on-site fuel storage.

4. Aviation Bowsers

These are specially designed bowsers that meet aviation safety standards for the transport and refueling of aircraft. They include filtration systems and grounding mechanisms to prevent static discharge.

5. Marine Fuel Bowsers

Used in harbors or onboard vessels, these are designed to safely deliver fuel to boats and ships, taking into account marine-specific environmental and safety requirements.

Components of a Fuel Bowser

A fuel bowser consists of several key components that ensure safe and efficient fuel handling:

- Tank: The main body that stores the fuel. It is typically made from carbon steel, stainless steel, or aluminum, depending on the type of fuel stored.

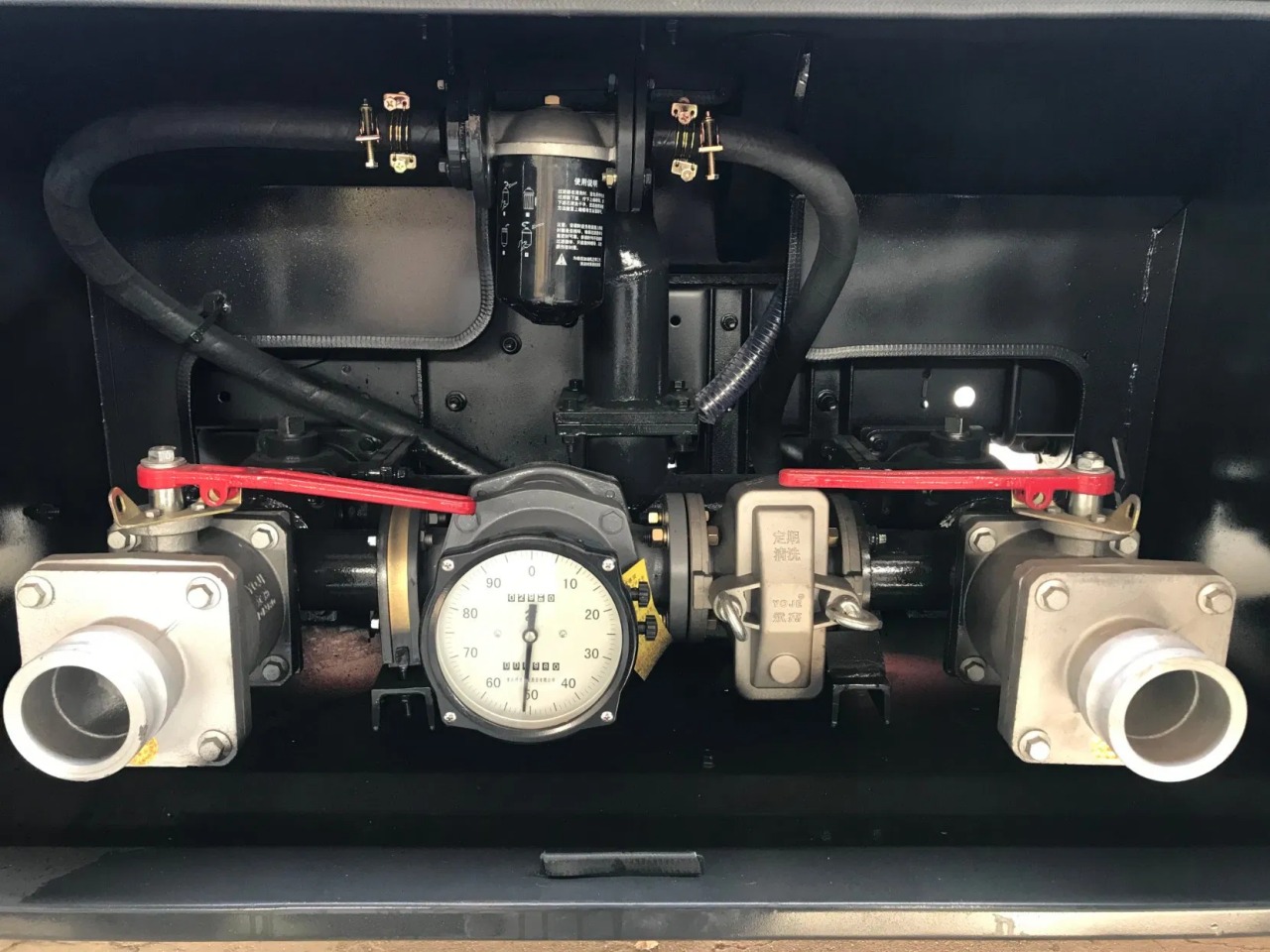

- Pump: Either manual or motorized, used to transfer fuel from the bowser to the target equipment or vehicle.

- Hose and Nozzle: Connects the pump to the refueling point. Nozzles can be automatic shutoff types for safety and convenience.

- Fuel Meter: Measures the amount of fuel dispensed.

- Vent System: Prevents pressure build-up during filling and dispensing.

- Spill Containment: Some models feature bunded tanks—double-walled designs that contain spills in case of tank failure.

- Lockable Cabinet: Houses the pump, meter, and hose, offering protection and security.

- Lighting and Reflectors: Essential for safety during night operations, particularly for road-towable units.

Common Applications

Fuel bowsers serve a wide range of industries and purposes:

1. Construction Sites

Machinery such as excavators, bulldozers, and generators needs regular refueling. A fuel bowser allows on-site refueling, eliminating downtime and transportation to off-site fueling stations.

2. Agriculture

In farming, where tractors, harvesters, and irrigation pumps work in remote fields, bowsers bring fuel directly to the equipment.

3. Military and Emergency Services

Rapid deployment of fuel is crucial during disaster response or military operations. Bowsers allow for mobile, tactical fuel distribution.

4. Mining Operations

Remote and large-scale mining operations often operate 24/7 and depend on a constant fuel supply. Fuel bowsers ensure efficient onsite delivery.

5. Aviation and Airports

Refueling aircraft—especially small planes and helicopters—often requires portable bowsers that can move between hangars and landing strips.

Advantages of Using Fuel Bowsers

Using fuel bowsers offers several logistical and economic benefits:

- Mobility: The ability to bring fuel to any location improves operational efficiency.

- Time-Saving: Reduces downtime by eliminating trips to fuel stations.

- Cost Efficiency: Enables bulk fuel purchasing and on-site storage.

- Versatility: Customizable designs allow for different fuel types and dispensing needs.

- Emergency Readiness: Vital in disaster recovery and remote site deployments.

Safety and Regulatory Considerations

Because fuel is highly flammable and environmentally hazardous, operating a fuel bowser involves strict compliance with safety standards and regulations:

1. ADR Compliance (Europe)

For bowsers transporting fuel on public roads, compliance with the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) is mandatory. This includes specifications for tank construction, labeling, and emergency equipment.

2. UN Certification

Tanks often carry UN markings indicating they meet international standards for the transport of dangerous goods.

3. Fire and Explosion Protection

This includes anti-static measures, grounding cables, and flame arrestors to minimize the risk of ignition.

4. Environmental Regulations

Fuel spills can cause significant soil and water contamination. Bunded designs and spill kits are often required to comply with environmental protection laws.

5. Training

Operators must be trained in the safe handling of fuels, operation of bowsers, and emergency response procedures.

Innovations in Fuel Bowsers

Modern fuel bowsers are being integrated with new technologies to enhance performance and monitoring:

- Telematics: Enables remote monitoring of fuel levels, location tracking, and usage reporting.

- Solar-Powered Pumps: An eco-friendly option for remote locations.

- Smart Dispensing Systems: Access-controlled fueling with RFID or PIN, ensuring only authorized personnel can dispense fuel.

- Multi-Compartment Tanks: Allow for the storage of different fuel grades or additives in a single unit.

Conclusion

A fuel bowser is much more than just a fuel tank on wheels—it is a critical logistical tool that supports numerous industries by ensuring the continuous and safe supply of fuel wherever it’s needed. Whether in construction, agriculture, aviation, or emergency services, fuel bowsers provide the mobility, efficiency, and reliability needed to keep operations running smoothly. As industries grow and become more remote and automated, the importance of well-designed, compliant, and technologically advanced fuel bowsers will only continue to rise.