In the world of global logistics and bulk liquid transportation, the 20 ISO tank plays a critical role. Whether you’re transporting chemicals, food-grade liquids, or gases, these standardized containers offer a safe, efficient, and versatile solution. But what exactly is a 20 ISO tank, and why is it so widely used? This article explores the design, specifications, advantages, applications, and safety features of 20 ISO tanks, providing a comprehensive understanding of their role in modern transport.

Understanding ISO Tanks

To begin, ISO tanks are intermodal containers built according to standards set by the International Organization for Standardization (ISO). This standardization allows them to be used seamlessly across various modes of transport—ships, trains, and trucks—without the need for unloading and reloading the contents. ISO tanks are primarily used to transport liquids, gases, and powders in bulk.

The number in the name, such as 20 ISO tank, refers to the length of the tank container in feet. Therefore, a 20 ISO tank is 20 feet long, aligning with standard container dimensions for compatibility with container ships and port handling equipment.

Design and Construction of a 20 ISO Tank

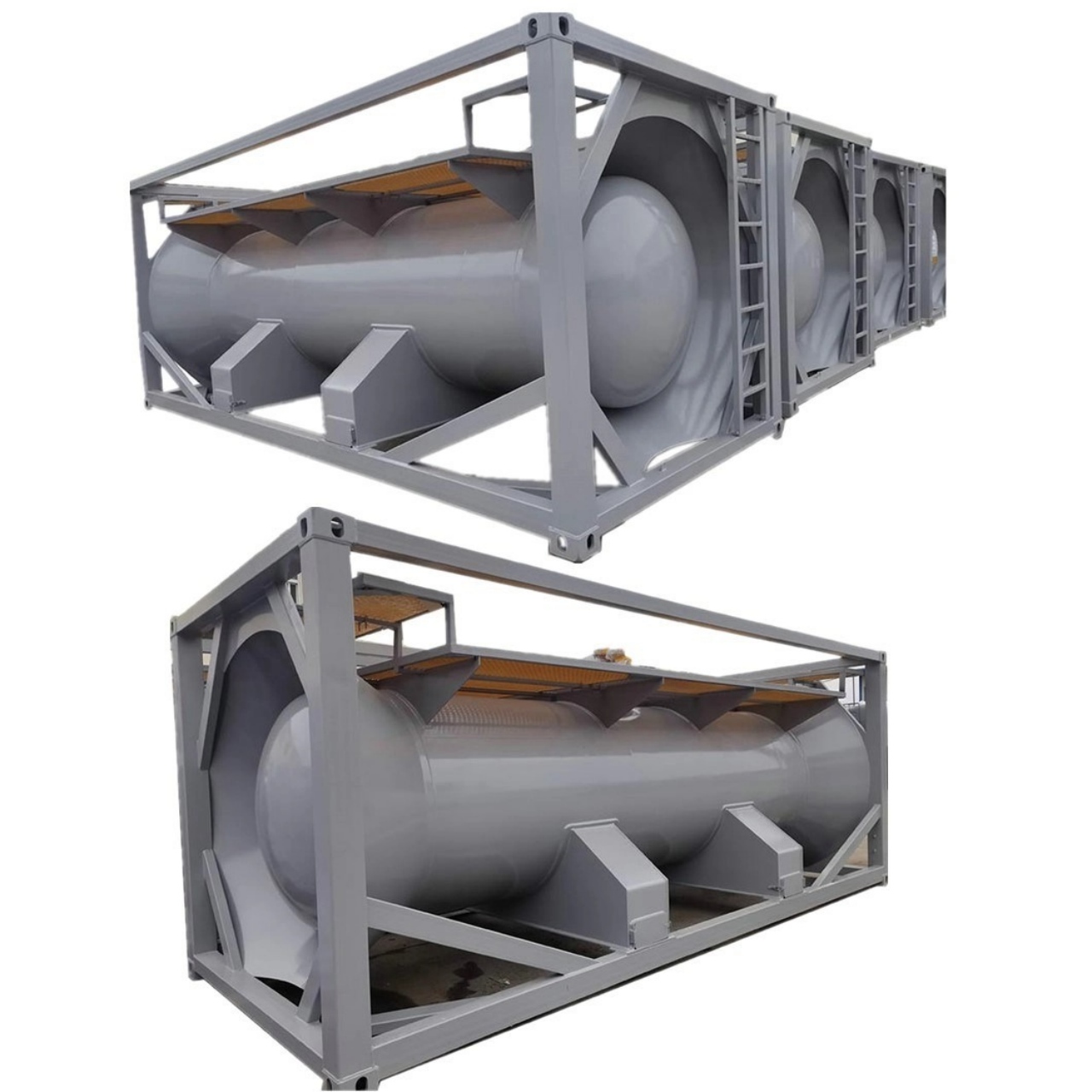

A typical 20-foot ISO tank consists of a cylindrical stainless steel pressure vessel mounted within a rectangular steel frame that complies with ISO 668 standards. The external frame measures approximately 20 feet (6.06 meters) long, 8 feet (2.44 meters) wide, and 8 feet 6 inches (2.59 meters) high.

Key components include:

- Inner Tank: Usually made from 316L stainless steel for chemical resistance.

- Insulation: Many ISO tanks are insulated with polyurethane foam or rock wool, especially those used for temperature-sensitive liquids.

- Frame: The protective outer frame is made from carbon steel, designed to withstand the rigors of transportation and allow for easy handling via cranes or forklifts.

- Valves and Fittings: A 20 ISO tank includes manholes, top and bottom discharge valves, pressure relief valves, and steam heating or cooling coils, depending on its application.

Capacity and Dimensions

Although all 20 ISO tanks share similar external dimensions, their internal capacities and design specifications can vary based on the product they are meant to carry.

Typical specifications include:

- Capacity: 14,000 to 26,000 liters (3,698 to 6,868 gallons)

- Tare Weight: Approximately 3,500 to 4,000 kg

- Maximum Gross Weight: Up to 36,000 kg

- Working Pressure: 4 to 6 bar (can go higher for specialized pressure tanks)

The capacity chosen depends on the density and hazard classification of the cargo, as well as any regulatory restrictions related to transport.

Types of 20 ISO Tanks

There are several variants of 20 ISO tanks, each tailored for specific materials:

- Standard ISO Tank: For non-hazardous or low-hazard liquids.

- Food-Grade ISO Tank: Designed for transporting consumable liquids like wine, milk, or edible oils. These tanks meet strict hygiene and material standards.

- Chemical ISO Tank: Built for corrosive or hazardous chemicals. These may include special linings or coatings.

- Gas ISO Tank (T50/T75): Designed for the transport of pressurized or refrigerated liquefied gases like LPG, LNG, or ammonia.

- Reefer ISO Tank: Equipped with a refrigeration unit to transport temperature-sensitive liquids.

- Swap Body Tank: Longer than 20 feet but still built with ISO-compatible fittings, these offer increased capacity within certain geographic limits (mainly in Europe).

Advantages of Using a 20 ISO Tank

The 20 ISO tank offers several distinct advantages over traditional methods of liquid transport, such as drums or IBCs (Intermediate Bulk Containers):

1. Efficiency

A single 20 ISO tank can carry the equivalent of 80 to 100 standard drums, significantly reducing packaging waste and manual handling.

2. Intermodal Capability

Thanks to its ISO-compliant dimensions and fittings, the tank can be easily transferred between trucks, ships, and trains without unloading.

3. Safety

With robust stainless steel construction, pressure relief systems, and containment features, ISO tanks provide 1 of the safest methods of transporting hazardous and non-hazardous materials.

4. Cost-Effective

Fewer man-hours, less packaging, and reduced product loss or contamination make ISO tanks more economical over the long term.

5. Environmentally Friendly

Reusable over a lifespan of 20+ years, ISO tanks contribute to reduced waste and environmental impact compared to single-use packaging.

Common Applications

20 ISO tanks are used in a broad spectrum of industries:

- Chemical Industry: Transporting solvents, acids, resins, and other industrial chemicals.

- Food and Beverage: Shipping edible oils, wine, juice concentrates, and dairy products.

- Pharmaceuticals: Delivering pharmaceutical-grade liquids under sterile conditions.

- Petroleum and Gas: Moving liquid petroleum gases (LPG), natural gas (LNG), and fuels.

- Agriculture: For liquid fertilizers and pesticides.

Thanks to their versatility and reliability, 20 ISO tanks are often the first choice for companies with global distribution needs.

Safety and Compliance

Transporting bulk liquids, especially hazardous ones, requires strict adherence to international regulations. ISO tanks must comply with standards such as:

- IMDG Code (International Maritime Dangerous Goods)

- ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road)

- RID (Regulations concerning the International Carriage of Dangerous Goods by Rail)

- CSC (Container Safety Convention)

These regulations govern the labeling, handling, inspection intervals, and maintenance of ISO tanks. Typically, tanks must be inspected and certified every 2.5 years for intermediate inspections and every 5 years for full certifications.

Conclusion

The 20 ISO tank is a cornerstone of modern liquid logistics. Its standardized size, robust design, and multi-modal capability make it the go-to solution for transporting liquids and gases safely and efficiently around the world. Whether you’re a logistics provider, a manufacturer, or a chemical supplier, understanding the capabilities and features of a 20 ISO tank can help streamline your operations and ensure compliance with international transport standards.

As industries continue to globalize and emphasize sustainability, the demand for ISO tanks is expected to rise. Their ability to provide cost-effective, safe, and environmentally friendly bulk transport positions them as a vital asset in global supply chains.