Introduction:

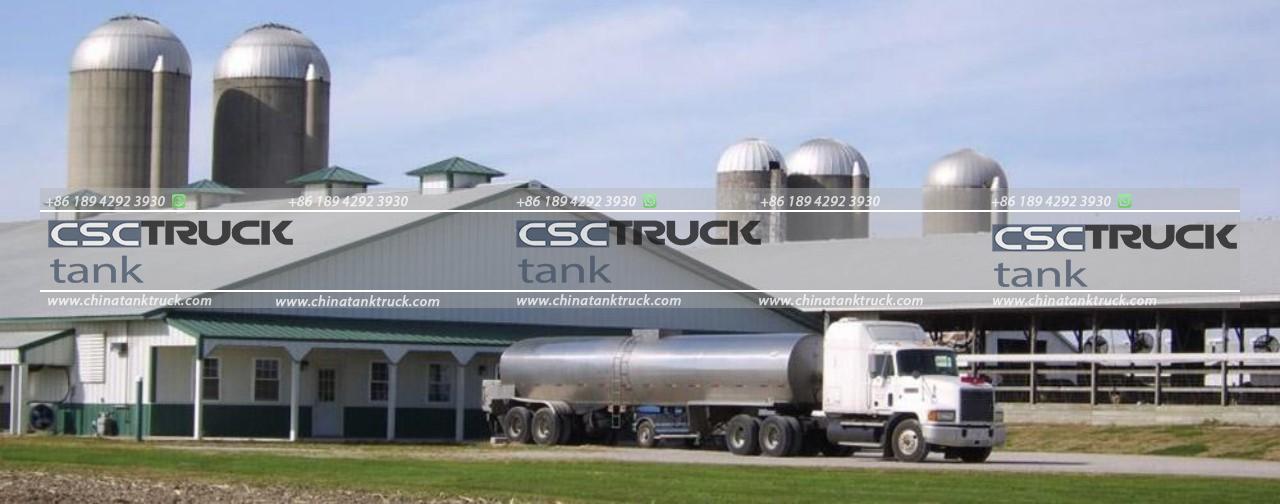

Milk is a perishable product that requires proper handling and transportation to maintain its freshness and hygiene. One crucial aspect of milk transportation is the use of milk tank trucks, specialized vehicles designed to preserve the quality of milk during transit. These trucks are equipped with various features and systems that ensure the preservation of freshness and hygiene. In this article, we will explore the mechanisms and processes involved in maintaining freshness and hygiene in a milk tank truck.

- Specialized Tank Design:

Milk tank trucks are designed with specialized tanks made of food-grade stainless steel. The stainless steel material is non-reactive and prevents contamination while maintaining the freshness of the milk. These tanks are also equipped with airtight seals to prevent external elements from entering the tank, such as dust, insects, or microorganisms that could compromise the quality of the milk.

- Temperature Control:

Maintaining the proper temperature is vital for preserving milk freshness. Milk tank trucks employ advanced temperature control systems to regulate and monitor the temperature inside the tank. These systems use refrigeration units or insulation techniques to keep the milk at the desired temperature during transportation. The temperature control system ensures that the milk remains within a specific range, inhibiting bacterial growth and maintaining freshness.

- Cleaning and Sanitization:

Hygiene is of utmost importance when it comes to milk transportation. Milk tank trucks undergo rigorous cleaning and sanitization processes to prevent contamination and ensure the highest standards of hygiene. After each use, the tanks are thoroughly cleaned using high-pressure water jets and specialized cleaning agents to remove any residue or bacteria. Regular sanitization practices, including the use of sanitizing agents, help eliminate potential pathogens and maintain the cleanliness of the tank.

- Air Filtration Systems:

Air quality within the milk tank truck is critical to prevent contamination. Specialized air filtration systems are installed to purify the air inside the tank, removing any dust particles, odors, or microorganisms. These filtration systems typically consist of high-efficiency particulate air (HEPA) filters that capture and trap airborne contaminants effectively, ensuring a clean and sterile environment for the milk.

- Monitoring and Quality Assurance:

To maintain freshness and hygiene, milk tank trucks incorporate advanced monitoring systems. These systems continuously monitor various parameters such as temperature, pressure, and milk quality during transportation. Real-time monitoring allows immediate detection of any deviations from optimal conditions, enabling prompt corrective action to be taken. Additionally, some tank trucks are equipped with GPS tracking systems, ensuring that the milk is delivered within the desired time frame and minimizing any potential delays that could affect freshness.

- Compliance with Regulations:

Milk tank trucks must adhere to strict regulatory standards to ensure the safety and quality of the milk. These standards vary across jurisdictions but often include guidelines on tank design, cleaning procedures, temperature control, and transportation practices. By complying with these regulations, milk tank trucks are subject to regular inspections and audits to verify their adherence to the necessary hygiene and safety requirements.

- Training and Expertise:

Maintaining freshness and hygiene in milk tank trucks requires skilled personnel who are trained in proper handling procedures. The drivers and operators of these vehicles receive specialized training on milk transportation, including best practices for cleanliness, temperature control, and monitoring. Regular training sessions and refresher courses ensure that the individuals involved are well-versed in maintaining the quality of the milk throughout the transportation process.

Conclusion:

Milk tank trucks play a crucial role in maintaining the freshness and hygiene of milk during transportation. Through specialized tank design, temperature control, cleaning and sanitization processes, air filtration systems, monitoring systems, adherence to regulations, and trained personnel, these trucks ensure that the milk arrives at its destination in optimal condition. The commitment to freshness and hygiene not only preserves the quality of the milk but also upholds consumer safety and satisfaction. The stringent measures and protocols followed by milk tank trucks contribute to the overall integrity of the dairy industry and instill confidence in consumers.

By utilizing food-grade stainless steel tanks, milk tank trucks prevent contamination and maintain the freshness of the milk. The airtight seals further safeguard against external elements that could compromise the quality of the product. This attention to detail ensures that the milk remains untainted and free from any foreign substances, providing consumers with a safe and wholesome product.

Temperature control is another critical factor in preserving milk freshness. The advanced temperature control systems employed by milk tank trucks ensure that the milk is maintained within a specific range throughout the transportation process. By utilizing refrigeration units or insulation techniques, the trucks prevent the growth of harmful bacteria, thus extending the shelf life of the milk and ensuring that it reaches consumers in optimal condition.

The cleaning and sanitization processes undertaken by milk tank trucks are rigorous and thorough. The tanks are subjected to intense cleaning procedures using high-pressure water jets and specialized cleaning agents. This eliminates any residue or bacteria that may be present, minimizing the risk of contamination. Regular sanitization practices further bolster hygiene standards, reducing the potential for pathogens to compromise the milk’s quality.

To maintain a sterile environment within the tank, milk tank trucks are equipped with air filtration systems. These systems effectively purify the air inside the tank, removing dust particles, odors, and microorganisms. By ensuring clean air circulation, the risk of contamination is minimized, and the milk remains untainted throughout the transportation process.

Monitoring systems are integral to maintaining freshness and hygiene in milk tank trucks. Real-time monitoring of temperature, pressure, and milk quality allows for immediate identification of any deviations from optimal conditions. Prompt corrective action can be taken, ensuring that the milk remains within the desired parameters. The inclusion of GPS tracking systems enables efficient delivery, minimizing any potential delays that could compromise the freshness of the milk.

Compliance with regulations is a fundamental aspect of milk transportation. Milk tank trucks must adhere to strict regulatory standards set by authorities to guarantee safety and quality. These regulations cover various aspects, including tank design, cleaning procedures, temperature control, and transportation practices. Regular inspections and audits ensure that milk tank trucks comply with these standards, providing an additional layer of assurance regarding freshness and hygiene.

The personnel involved in milk transportation undergo specialized training to ensure the highest standards of quality and hygiene. Drivers and operators are educated on best practices for cleanliness, temperature control, and monitoring. Regular training sessions and refresher courses equip them with the necessary knowledge and expertise to handle milk tank trucks effectively. Their commitment to maintaining freshness and hygiene contributes to the overall integrity of the milk transportation process.

In conclusion, milk tank trucks are designed and operated with meticulous attention to detail to maintain the freshness and hygiene of milk during transportation. Through specialized tank design, temperature control, cleaning and sanitization processes, air filtration systems, monitoring systems, adherence to regulations, and trained personnel, these trucks ensure that the milk reaches consumers in optimal condition. By upholding the highest standards of freshness and hygiene, milk tank trucks not only preserve the quality of the milk but also enhance consumer safety and confidence in the dairy industry.