Pneumatic trailers are vital components of the transportation industry, specifically designed to haul dry bulk materials such as cement, sand, flour, and plastic pellets. These trailers utilize compressed air to unload their cargo efficiently, making them essential for industries requiring bulk material transport. The pressure system that enables them to function effectively and safely is central to their operation.

Understanding Pneumatic Trailers

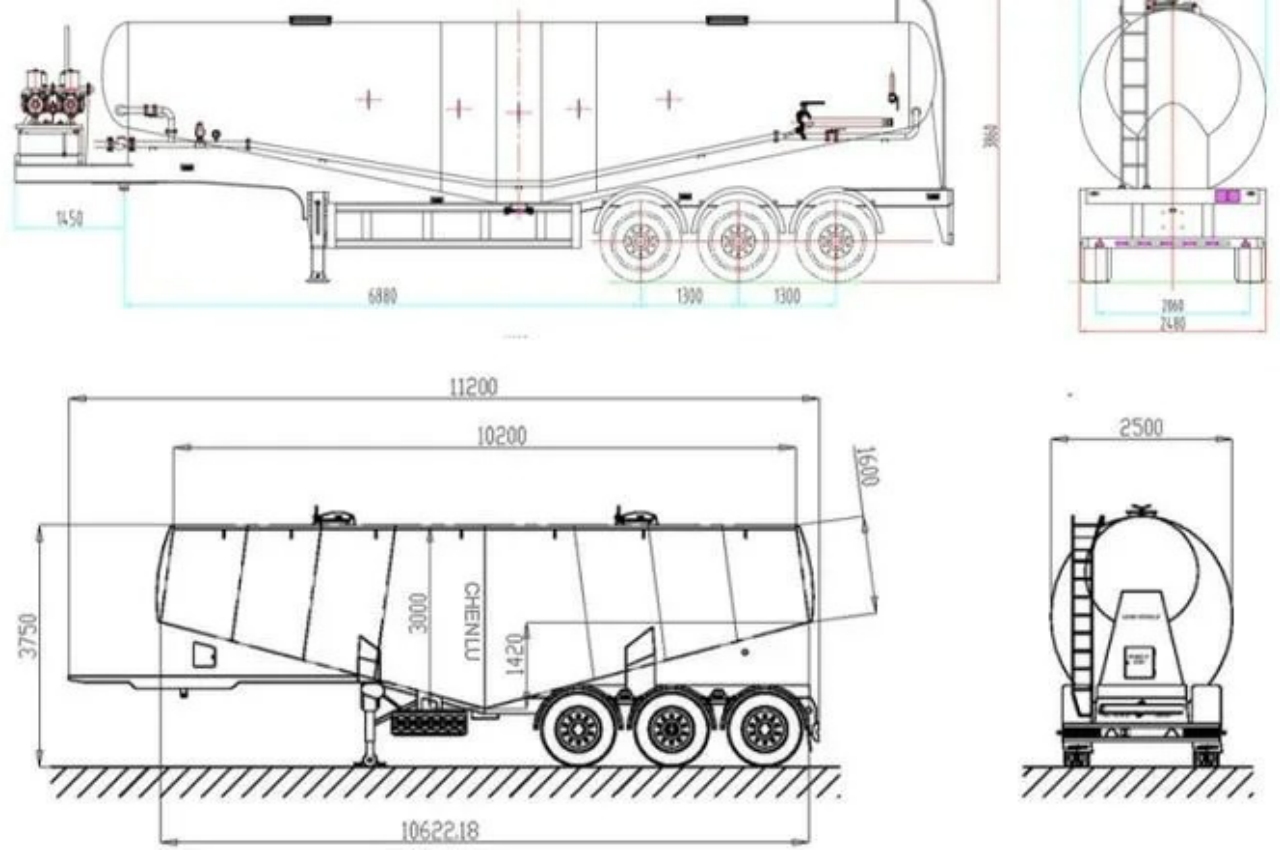

Pneumatic trailers, known as dry bulk trailers, come in various designs tailored to specific cargo requirements. They typically consist of a large cylindrical tank mounted on a trailer chassis. The tank is equipped with multiple compartments to accommodate different materials, ensuring versatility in transport.

The trailers are engineered to handle high-pressure environments due to the nature of their cargo and the unloading process. The pressure within these trailers is carefully regulated to maintain optimal conditions for both transport and discharge.

Pressure Regulation and Safety

The pressure inside a pneumatic trailer is a critical factor in ensuring safe transportation and unloading. It is regulated by sophisticated pneumatic systems that control air flow into and out of the tank. The pressure must be carefully monitored to prevent over-pressurization, which could lead to structural damage or even catastrophic failure.

Modern pneumatic trailers are equipped with advanced pressure gauges and safety valves to maintain safe operating conditions. These valves automatically release excess pressure to prevent buildup beyond safe limits, safeguarding both the trailer and its surroundings.

Cargo Considerations

The pressure within a pneumatic trailer varies depending on several factors, including the type of cargo being transported and the specific requirements of the unloading process. Different materials may necessitate varying levels of pressure to ensure efficient flow during unloading while minimizing the risk of contamination or degradation.

For instance, materials like cement or sand often require higher pressures to facilitate rapid unloading without clogging or blockages. In contrast, lighter materials such as flour or plastic pellets may require lower pressures to prevent damage during transport and discharge.

Operational Challenges and Solutions

Operating pneumatic trailers presents unique challenges, particularly concerning pressure management. Transporting materials over long distances and varying terrains demands robust systems capable of adapting to changing conditions without compromising safety or efficiency.

Engineers and manufacturers continuously innovate to enhance pneumatic trailer designs, focusing on optimizing pressure control systems. This includes integrating state-of-the-art sensors, valves, and automation technologies to streamline operations and improve reliability.

Environmental and Regulatory Considerations

The pressure within pneumatic trailers also intersects with environmental and regulatory frameworks. Transporting bulk materials efficiently while minimizing environmental impact is a priority for many industries. Pressure regulation plays a crucial role in achieving these goals by reducing energy consumption and emissions associated with transport operations.

Regulatory bodies enforce standards governing pneumatic trailer operations, including pressure specifications and safety protocols. Compliance ensures that trailers meet stringent requirements for performance and environmental stewardship, fostering sustainable practices within the transportation sector.

Future Trends and Innovations

Looking ahead, the evolution of pneumatic trailers continues with advancements in pressure management and overall efficiency. Emerging technologies such as predictive analytics and remote monitoring systems offer unprecedented insights into trailer performance, enabling proactive maintenance and operational optimization.

Innovations in materials science and engineering are also driving improvements in pneumatic trailer design. Lightweight materials and aerodynamic enhancements contribute to fuel efficiency, while enhanced pressure control systems further refine cargo handling capabilities.

Conclusion

The pressure within a pneumatic trailer is not merely a technical detail but a critical aspect of its functionality and safety. From transporting bulk materials to facilitating efficient unloading, pressure regulation defines the operational parameters of these essential transport vehicles. As industries evolve and technological innovations accelerate, pneumatic trailers will continue to play a pivotal role in the global supply chain, ensuring the seamless delivery of essential goods while adhering to stringent safety and environmental standards.

In summary, understanding the pressure dynamics within pneumatic trailers underscores their significance in modern logistics and highlights ongoing efforts to enhance their efficiency, safety, and sustainability.