In the world of logistics, aviation, construction, mining, and even agriculture, the term “fueling bowser“ often comes up. Despite its frequent use in these industries, many outside these sectors may not know exactly what a fueling bowser is or what role it plays. A fueling bowser, also known simply as a fuel bowser or fuel truck, is a specialized vehicle designed to store, transport, and dispense fuel, typically diesel, petrol, aviation fuel, or other liquid fuels. This article delves into the design, function, types, and uses of fueling bowsers, as well as their importance in modern industrial operations.

The Basics: What is a Fueling Bowser?

A fueling bowser is essentially a mobile fuel tank mounted on a vehicle chassis, trailer, or skid. It is used to deliver fuel to vehicles, machinery, equipment, or even aircraft in remote locations or areas where traditional fueling stations are not accessible.

The term “bowser” has its origins in the early 20th century, named after Sylvanus Bowser, an American inventor who created the first fuel pump. Over time, the word came to be associated not only with fuel dispensers but also with mobile fuel distribution units.

Key Components of a Fueling Bowser

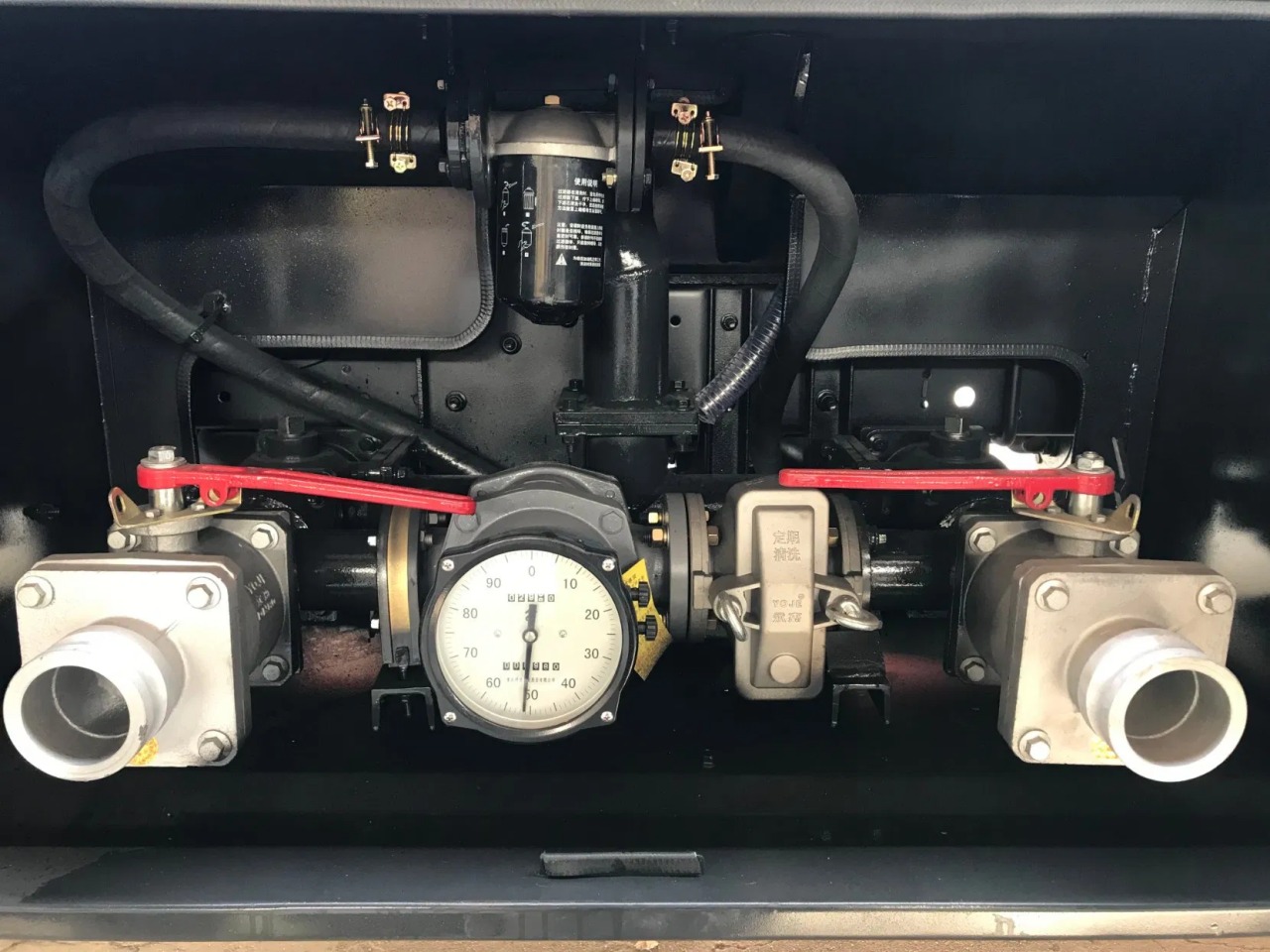

While the design of a fueling bowser can vary based on its intended use and capacity, most units share several common components:

- Fuel Tank

The tank is the core component of any Bowser. Made from steel or aluminum (and in some cases stainless steel for chemical resistance), the tank is built to store fuel safely. It is often partitioned for structural integrity and to reduce fuel sloshing. - Chassis or Mounting Base

Depending on the application, the fuel tank is mounted on a vehicle chassis (like a truck), a trailer, or a static skid. Mobile bowsers allow fuel delivery to remote or difficult-to-reach sites. - Pump System

A mechanical or electric pump is used to transfer fuel from the tank to the receiving equipment. These can be engine-driven, battery-powered, or PTO-driven (Power Take-Off from the truck engine). - Hoses and Nozzles

A dispensing hose, usually with an automatic shutoff nozzle, allows precise control over fuel delivery. In aviation and specialized applications, reels and filters may be added to ensure clean fuel flow. - Metering System

Many fueling bowsers include digital or analog flow meters to measure the amount of fuel dispensed, useful for record-keeping and billing. - Safety Equipment

Fire extinguishers, grounding reels, emergency stop systems, and pressure-relief valves are standard to ensure safe operation.

Types of Fueling Bowsers

Fueling bowsers come in several types based on their structure and purpose:

1. Truck-Mounted Bowsers

These are mounted on the back of a commercial truck chassis and are widely used in industries like construction, transportation, and mining. They typically carry between 1,000 to 30,000 liters of fuel.

2. Trailer Bowsers

Mounted on 2 or 4-wheel trailers, these are designed for towing behind a vehicle. Trailer bowsers are common on farms, construction sites, and military operations, where portability is essential.

3. Aviation Refuelers

Specialized fuel bowsers are used at airports for fueling aircraft. These often include filtration systems, grounding systems, and long hose reels to safely refuel small aircraft, helicopters, or large commercial planes.

4. Static Bowsers

These are stationary units, sometimes used as temporary fuel stations. They are mounted on skids or frames and placed at job sites for regular fuel dispensing to machinery.

Common Fuel Types Carried by Bowsers

Fueling bowsers can carry various fuel types depending on their material and design certification. These include:

- Diesel fuel – Most commonly used in construction and agricultural bowsers.

- Petrol (Gasoline) – Used for general vehicle fueling.

- Aviation fuel (Jet A1, Avgas) – Requires specialized equipment and safety measures.

- Kerosene and biodiesel – In niche industrial or alternative energy applications.

Applications and Industry Use

The versatility of fueling bowsers makes them essential in several industries:

1. Construction and Mining

In off-grid construction sites and large-scale mining operations, fueling bowsers are critical. Heavy equipment such as excavators, bulldozers, and cranes relies on bowsers for on-site fueling, ensuring minimal downtime.

2. Agriculture

Farmers use trailer-mounted bowsers to refuel tractors, harvesters, and other equipment spread over large fields. This reduces time lost in traveling to distant fuel stations.

3. Aviation

Airports and private airstrips rely on aviation bowsers to fuel aircraft efficiently. These units must comply with stringent aviation standards to prevent fuel contamination and ensure safe operation.

4. Military and Emergency Services

In combat zones or disaster-struck areas, mobile fueling units are crucial for maintaining vehicle mobility and powering generators or other essential equipment.

5. Transportation and Logistics

Fleet operators use bowsers to refuel trucks at depots or roadside. This saves time and improves fleet management efficiency.

Safety and Compliance

Because fueling bowsers deal with flammable liquids, safety and regulatory compliance are top priorities. In most countries, these units must meet transport regulations, such as:

- ADR (Accord Dangereux Routier) compliance in Europe.

- UN and DOT specifications in the United States.

- PESO (Petroleum and Explosives Safety Organisation) guidelines in India.

Manufacturers often integrate safety features like anti-spill mechanisms, fireproof materials, and emergency cutoffs. Operator training is also mandatory in many regions.

Advancements and Modern Trends

Modern fueling bowsers are evolving with advancements in technology and environmental regulation. Some of the notable trends include:

- Telematics integration – GPS tracking and fuel monitoring for real-time management.

- Solar-powered pumps – Eco-friendly options for remote locations.

- Smart meters – For accurate billing and inventory control.

- Double-skinned tanks – Enhanced safety against leaks and contamination.

Conclusion

A fueling bowser is far more than just a mobile fuel tank. It is a vital logistical tool that supports various industries by ensuring the reliable delivery of fuel wherever it is needed. From vast construction sites and remote farmlands to busy airports and emergency operations, bowsers serve as the backbone of mobile fuel supply. Their flexibility, safety, and reliability make them an indispensable part of modern infrastructure and operations.

As industries grow and technologies advance, fueling bowsers continue to adapt, becoming smarter, safer, and more efficient than ever before. Understanding what they are and how they work is key to appreciating their role in keeping the world running, one drop of fuel at a time.