Introduction

Water tank semi-trailers are essential for businesses that require bulk water transportation. Whether for agriculture, construction, firefighting, or potable water delivery, selecting the right water tank semi-trailer is crucial for efficiency and cost-effectiveness. This guide will help you evaluate the key factors to consider when purchasing a water tank semi-trailer for your business.

1. Determine Your Business Needs

The first step in choosing a water tank semi-trailer is identifying your specific business requirements. Consider the following aspects:

- Application: Are you transporting potable water, industrial water, or firefighting water?

- Volume Requirements: How much water do you need to transport per trip?

- Frequency of Use: Will the trailer be used daily, weekly, or seasonally?

- Operational Environment: Are you operating on highways, off-road, or in extreme weather conditions?

Understanding these factors will help narrow down your options and find a trailer that best suits your business needs.

2. Tank Capacity and Size

Water tank semi-trailers come in different capacities, ranging from 5,000 to 50,000 liters or more. The right size depends on:

- Your transport needs: A larger tank may reduce the number of trips but could require a stronger tractor unit.

- Legal weight limits: Ensure the total weight of the trailer when fully loaded complies with local regulations.

- Road and site accessibility: If operating in confined spaces, a smaller, more maneuverable trailer may be preferable.

3. Tank Material Selection

The tank material affects durability, maintenance, and suitability for specific applications. Common materials include:

- Stainless Steel: Ideal for potable water and food-grade applications due to its corrosion resistance and cleanliness.

- Aluminum: Lighter than steel, resistant to corrosion, and suitable for potable and industrial water.

- Polyethylene (Plastic-Lined Tanks): Used for lower-cost solutions and non-potable water applications.

- Carbon Steel with Epoxy Lining: Common for industrial use but requires regular maintenance to prevent corrosion.

Your choice should be based on the type of water being transported and environmental conditions.

4. Trailer Configuration and Chassis Design

Different trailer configurations suit various operational needs:

- Single-axle vs. Multi-axle Trailers: More axles distribute weight better and allow for larger capacities.

- Frame Construction: Look for high-strength steel frames with anti-corrosion coatings.

- Suspension System: Air suspension is ideal for smooth rides, while leaf spring suspension offers durability for off-road use.

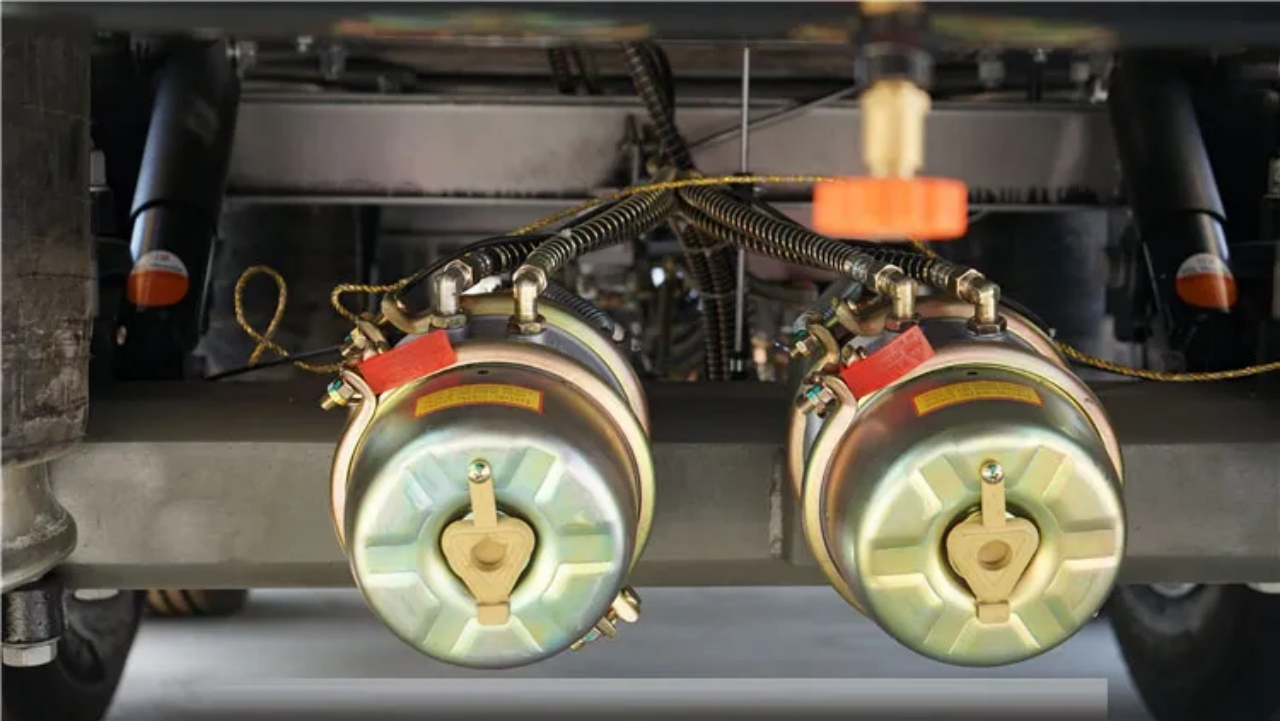

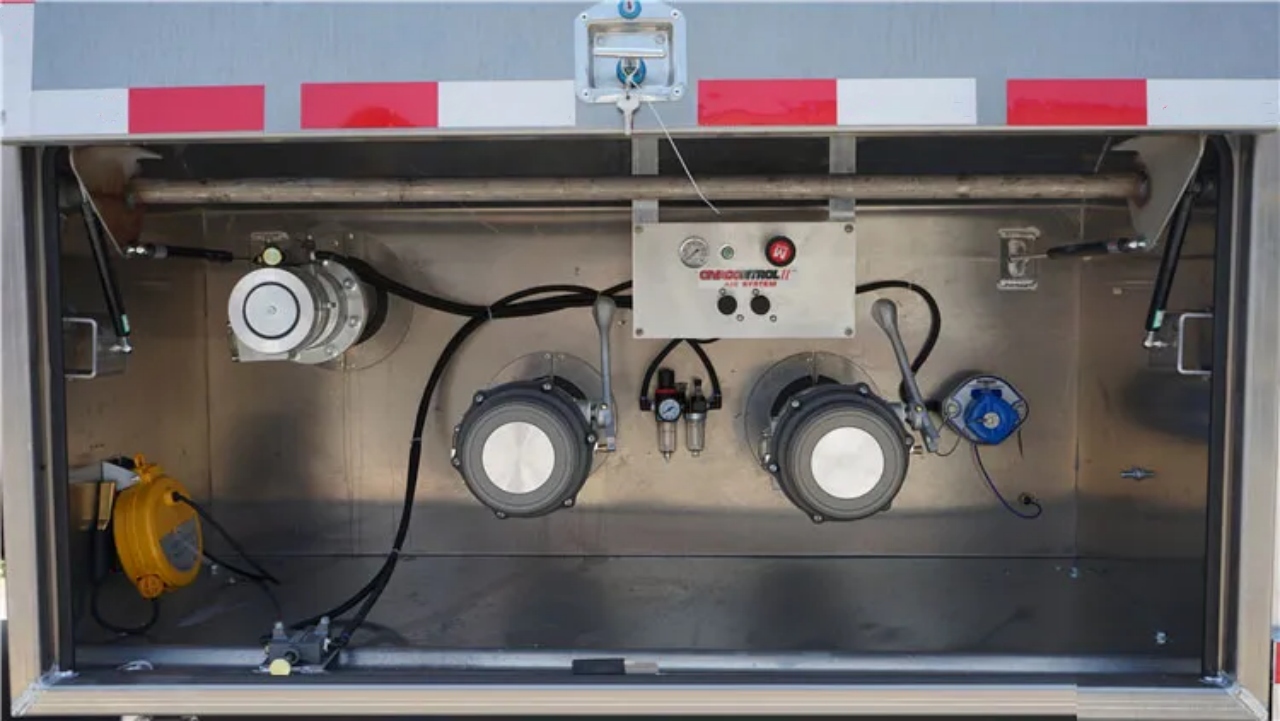

5. Pumping and Discharge System

The efficiency of loading and unloading water depends on the pumping and discharge system. Consider:

- Pump Type: PTO-driven, hydraulic, or electric-powered pumps depending on your operational setup.

- Discharge Valves: Check valve sizes and configurations to ensure quick unloading.

- Hose Reels and Nozzles: Essential for precise water distribution in applications like irrigation or firefighting.

6. Regulatory Compliance and Certifications

Ensure that the water tank semi-trailer complies with local and international regulations, including:

- DOT (Department of Transportation) Standards for highway transportation.

- NSF Certification for potable water tanks.

- ADR Compliance if transporting hazardous liquids.

- Weight and Dimension Regulations for road safety and legal compliance.

7. Maintenance and Longevity Considerations

Regular maintenance ensures the longevity of your trailer. Key factors to consider include:

- Ease of Cleaning: Tanks should have manholes and drain valves for easy cleaning.

- Corrosion Protection: Look for coated interiors and stainless-steel components.

- Replacement Parts Availability: Choose brands with readily available spare parts and service support.

- Warranty and Manufacturer Support: Opt for trailers with strong warranty coverage and reliable customer service.

8. Cost Considerations and Return on Investment

A cost-effective water tank semi-trailer balances upfront costs with long-term operational efficiency. Consider:

- Initial Purchase Price: Compare prices from multiple manufacturers.

- Operating Costs: Fuel efficiency, maintenance expenses, and insurance costs.

- Resale Value: High-quality trailers retain value better over time.

- Financing Options: Leasing or financing options may be available to ease the investment burden.

Conclusion

Choosing the right water tank semi-trailer involves evaluating your business needs, tank capacity, material selection, trailer configuration, and regulatory compliance. By considering maintenance requirements, cost factors, and long-term investment benefits, you can make an informed decision that maximizes efficiency and profitability. Investing in the right trailer ensures safe and efficient water transportation tailored to your business operations.