Water tank semi-trailers play a crucial role in transporting large quantities of water for various industries, such as agriculture, construction, fire protection, and municipal services. Choosing the right water tank semi-trailer can significantly impact the efficiency, safety, and cost-effectiveness of water transportation. In this complete guide, we will explore the key features to look for when selecting a water tank semi-trailer, ensuring you make an informed decision that suits your needs.

1. Tank Capacity

The capacity of the water tank is one of the most important features to consider when selecting a semi-trailer. Water tank semi-trailers come in various sizes, typically ranging from 3,000 liters (about 792 gallons) to 30,000 liters (about 7,920 gallons) or more. The right capacity depends on the specific requirements of your operation. For example:

- Agriculture: Farmers who need to irrigate large fields may require larger tanks, up to 20,000 liters or more.

- Construction: Water tanks for construction sites may need to carry a sufficient amount of water for dust suppression and concrete mixing, often ranging between 10,000 and 15,000 liters.

- Firefighting: Fire trucks and tankers typically require smaller tanks, often between 3,000 to 8,000 liters, for efficient and rapid deployment.

It’s essential to balance the required capacity with the weight limits of your towing vehicle, as larger tanks increase the overall weight.

2. Material of Construction

The material used in constructing the water tank is another crucial factor to consider. The tank should be durable, resistant to corrosion, and capable of maintaining the quality of the water during transportation. Common materials used include:

- Stainless Steel: Stainless steel tanks are the most durable and corrosion-resistant, making them ideal for transporting potable water. They are also easy to clean and maintain, ensuring the water remains safe for consumption.

- Aluminum: Aluminum tanks are lightweight and resistant to corrosion, which is especially useful in harsh weather conditions. They are a good option for transporting non-potable water or water in industrial applications.

- Polyethylene: Some tanks are made from high-density polyethylene (HDPE), which is cost-effective and resistant to corrosion. While not as durable as metal, these tanks are suitable for transporting water for agricultural or industrial use.

3. Shape and Design

The shape and design of the tank affect its functionality and ease of use. Water tanks come in various designs, such as cylindrical, elliptical, or square, with cylindrical tanks being the most common due to their structural integrity. Here are some design considerations:

- Cylindrical Tanks: These are the most common design and are ideal for long-distance transport as they provide even pressure distribution. They are particularly good for heavy-duty use.

- Elliptical Tanks: Elliptical or oval-shaped tanks are commonly used for improving aerodynamics, reducing wind resistance, and enhancing fuel efficiency when towing. However, they may have slightly reduced capacity compared to cylindrical tanks.

- Square or Rectangular Tanks: These designs maximize storage capacity, especially for smaller water loads. They are often used for municipal applications or smaller projects.

The design also impacts how the tank is mounted on the semi-trailer. The tank should be securely fixed to the frame to prevent shifting during transportation.

4. Material Lining and Coatings

The interior lining of the water tank is essential for maintaining the quality of the water being transported. A proper coating or lining will prevent contamination and corrosion from affecting the water. Some options include:

- Epoxy Coatings: Epoxy coatings are commonly used to line tanks, providing a layer of protection against corrosion and extending the life of the tank. They are especially important when transporting potable water.

- Food-Grade Liner: If the semi-trailer is used for carrying drinking water, the tank must be lined with a food-grade material. This ensures that no harmful chemicals leach into the water.

- Polyethylene Liner: Some tanks are lined with a polyethylene liner to protect the tank from corrosion and ensure the water remains free of contaminants. This is particularly important when transporting water in industries like agriculture or firefighting.

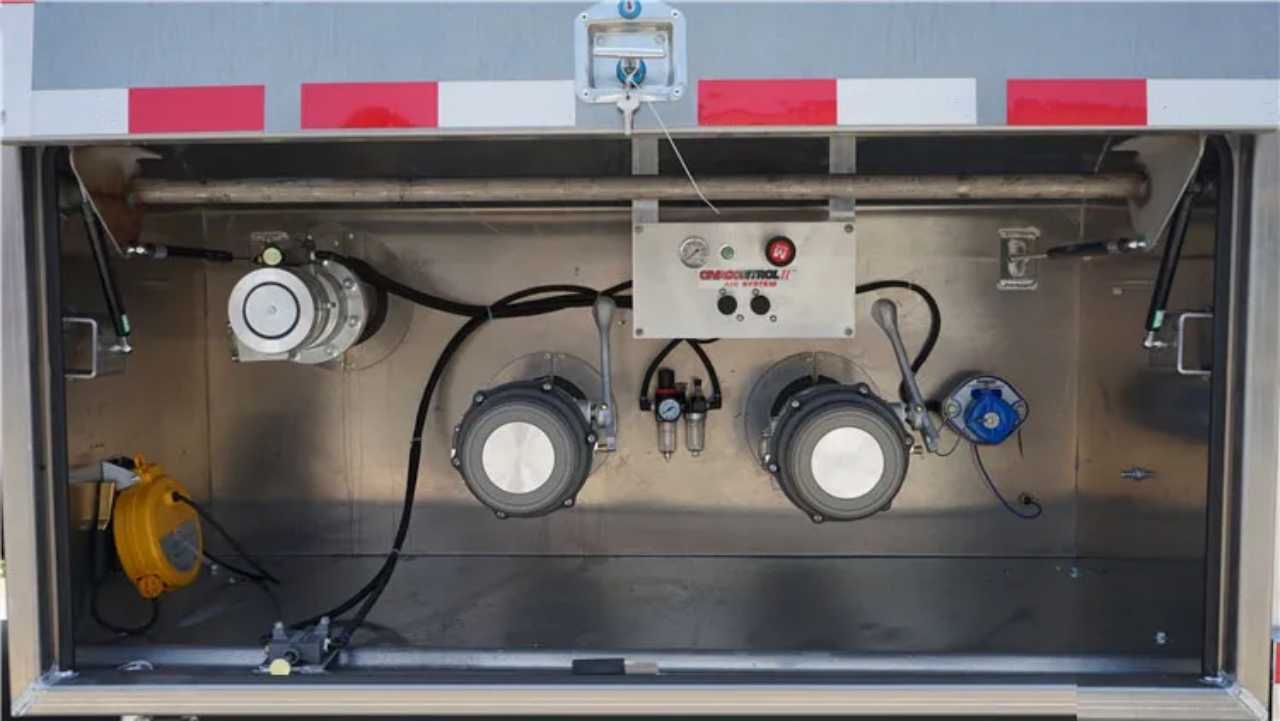

5. Pump and Valve Systems

Water tank semi-trailers are often equipped with pump and valve systems to control the flow of water during unloading. When selecting a semi-trailer, you need to consider the type and quality of the pump and valve systems:

- Pump Type: There are different types of pumps used in water tanks, such as centrifugal pumps, diaphragm pumps, or piston pumps. The pump type determines how efficiently water is transferred from the tank to the desired location. Centrifugal pumps are the most common due to their high efficiency and ease of use.

- Valves and Fittings: The valve system allows for precise control over the water flow. Ensure that the semi-trailer is equipped with high-quality valves made from durable materials like stainless steel to avoid leaks and maintain pressure control.

- Unloading Mechanism: Some water tank semi-trailers come with automatic or semi-automatic unloading systems. These systems reduce labor time and enhance the speed of water delivery, which is crucial in emergency situations, like firefighting.

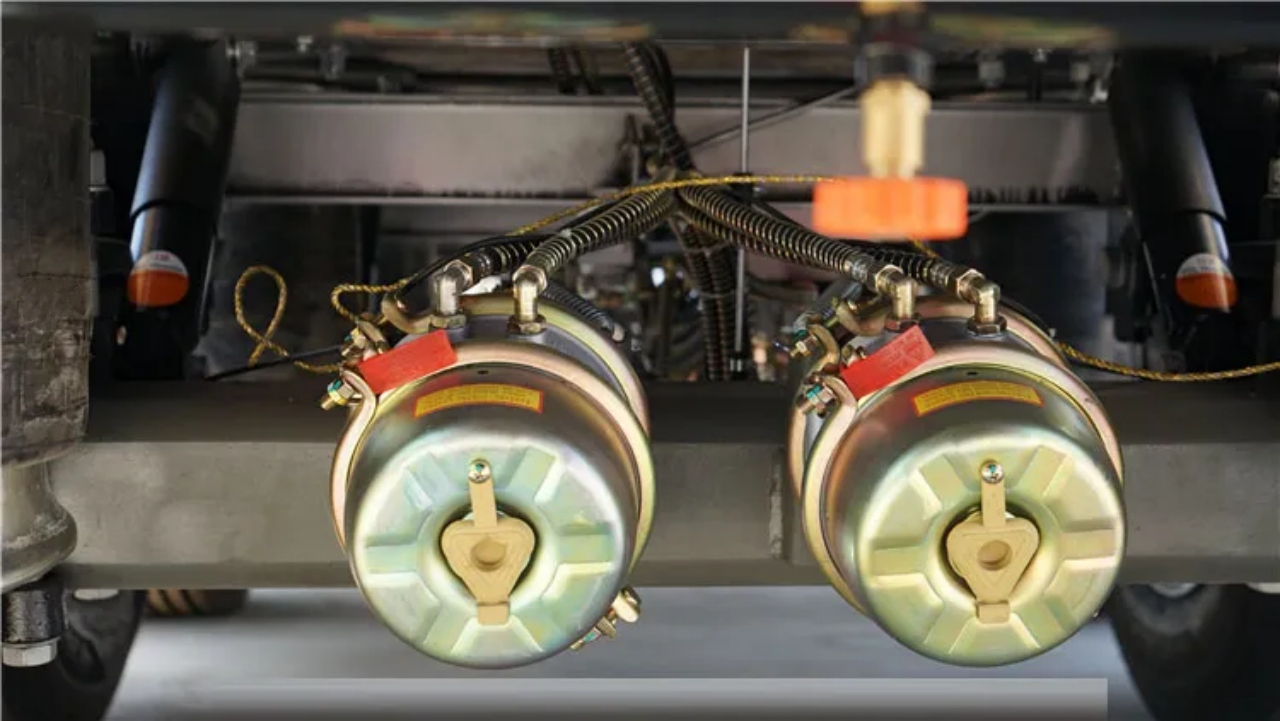

6. Braking and Suspension Systems

Due to the heavy load and potential instability of transporting water, it’s essential to consider the braking and suspension systems of the water tank semi-trailer. Proper braking and suspension systems ensure the safe operation of the trailer on various terrains:

- Air Brake System: Air brakes are commonly used in heavy-duty vehicles, including water tank semi-trailers, as they provide more stopping power, especially when hauling heavy loads. These systems are highly effective and ensure better control of the trailer.

- Suspension System: A well-designed suspension system helps maintain stability and reduces wear on both the trailer and the towing vehicle. For water tank trailers, an air-ride suspension system is ideal, as it provides better shock absorption and smoother operation over rough terrain.

7. Mobility and Maneuverability

Water tank semi-trailers must be easy to maneuver, particularly when delivering water to tight or hard-to-reach locations. Features that enhance maneuverability include:

- Axle Configuration: Depending on the trailer’s size and weight, water tank semi-trailers may have tandem or tri-axle configurations. Tandem axles are more suitable for smaller trailers, while tri-axle configurations are typically used for larger, heavier tanks.

- Steerable Axles: Some advanced water tank semi-trailers feature steerable axles, which allow for better turning radius and enhanced maneuverability. This is especially beneficial for water delivery in urban areas or construction sites.

8. Durability and Maintenance

A water tank semi-trailer needs to withstand harsh conditions, both on the road and in the elements. Durability and ease of maintenance are vital considerations when purchasing a water tank semi-trailer:

- Corrosion Resistance: As water is often transported in varying weather conditions, the trailer should be resistant to rust and corrosion. Stainless steel and aluminum tanks offer better resistance to corrosion compared to other materials.

- Ease of Maintenance: The tank should be easy to clean, and the components like pumps, valves, and filters should be accessible for maintenance and repairs. Regular inspection and cleaning of the tank and its components will prolong the life of the semi-trailer.

9. Compliance and Certifications

Finally, it’s crucial to ensure that the water tank semi-trailer meets all necessary regulations and standards for safe operation. Check for certifications that guarantee the tank’s suitability for transporting water, particularly potable water:

- ISO Certification: The tank should be built according to international standards, ensuring its durability and safety.

- Local Regulations: Depending on your location, the semi-trailer may need to comply with local road safety standards, weight limits, and environmental regulations.

Conclusion

When selecting a water tank semi-trailer, it’s essential to consider a combination of features that ensure functionality, durability, and safety. By focusing on tank capacity, material, design, pump systems, braking and suspension, maneuverability, maintenance, and regulatory compliance, you can make an informed decision that aligns with your operational needs. Choosing the right water tank semi-trailer not only ensures that water is efficiently transported but also enhances the longevity of the equipment, providing better returns on your investment.