The transportation of goods across the globe is a critical component of international trade and commerce. Among the myriad methods employed to move these goods, the cargo tank stands out as a highly specialized and vital tool, especially in the shipping and logistics industries. Understanding the purpose and functionality of cargo tanks is essential for appreciating their role in global trade.

Definition and Types of Cargo Tanks

A cargo tank is a type of container specifically designed for the storage and transportation of liquids, gases, or bulk materials. These tanks are typically found on cargo ships, trucks, and railway cars, and are engineered to handle a wide range of substances, including chemicals, petroleum products, food-grade liquids, and industrial gases.

Cargo tanks can be broadly categorized into several types based on their construction and intended use:

1. Tank Containers: These are used in intermodal transport, meaning they can be transferred between ships, trucks, and trains without unloading their contents. They are often used for transporting chemicals and food products.

2. Railroad Tank Cars: Specialized for rail transport, these tanks can carry bulk liquids and gases over long distances.

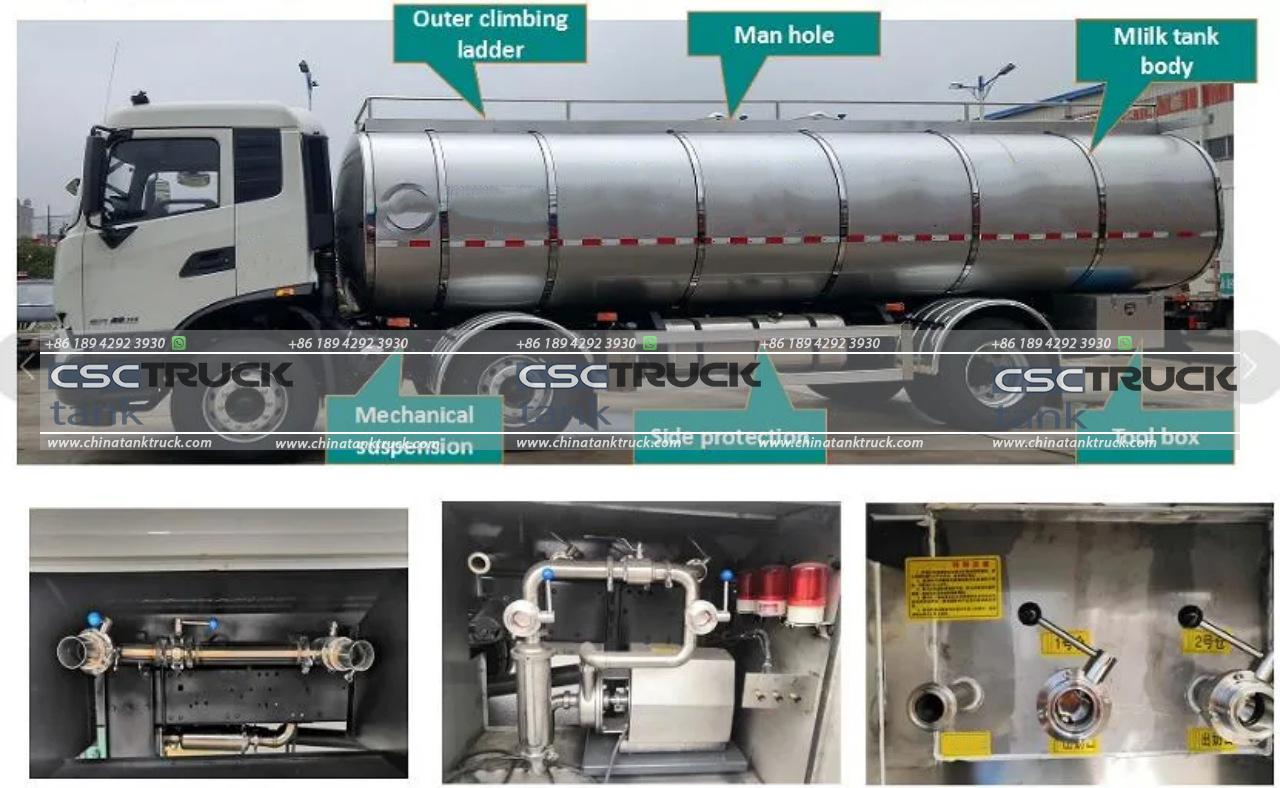

3. Road Tankers: Mounted on trucks, these are commonly seen on highways, delivering fuels, milk, chemicals, and other liquid goods.

4. Marine Tankers: Found on ships, these large tanks are used to transport substantial quantities of oil, liquefied natural gas (LNG), and other bulk liquids across oceans.

The Fundamental Purposes of Cargo Tanks

The primary purpose of a cargo tank is to safely and efficiently transport substances that are otherwise difficult to handle. This involves several key functions:

1. Containment: The foremost purpose of a cargo tank is to securely contain the substance being transported. This is particularly crucial for hazardous materials that can pose significant risks to health, safety, and the environment. Tanks are constructed using materials that can withstand the chemical and physical properties of their cargo, ensuring that there is no leakage or contamination.

2. Preservation of Cargo Quality: Many substances transported in cargo tanks, such as food-grade liquids and chemicals, require specific conditions to maintain their quality. Cargo tanks are often equipped with insulation, refrigeration units, or heating systems to ensure that the cargo remains within the required temperature range.

3. Efficiency in Transportation: Cargo tanks are designed to maximize the volume of goods transported while minimizing the space they occupy. This efficiency is crucial for reducing transportation costs and ensuring that the maximum possible amount of goods can be moved in a single trip. For instance, marine tankers are massive, often segmented into several compartments to optimize space utilization and maintain the ship’s balance.

4. Facilitation of Loading and Unloading: Efficient loading and unloading processes are critical for maintaining the supply chain’s speed. Cargo tanks are equipped with various mechanisms, such as pumps, valves, and hoses, to facilitate the swift transfer of their contents. Some tanks are designed with features that allow them to be easily connected to pipelines or other transport infrastructure.

5. Safety and Compliance: Transporting hazardous materials is subject to stringent regulations to ensure safety and environmental protection. Cargo tanks must comply with international and local standards, which dictate their design, construction, and maintenance. This includes features like pressure relief valves, emergency shutoff systems, and robust construction materials.

Specialized Features of Cargo Tanks

Cargo tanks incorporate a variety of specialized features to fulfill their purposes effectively:

1. Material Selection: The construction material of a cargo tank is chosen based on the type of cargo it will carry. For example, stainless steel is commonly used for food-grade and chemical tanks due to its resistance to corrosion and ease of cleaning. Aluminum and composite materials may be used for lighter-weight tanks.

2. Insulation and Temperature Control: Insulation is vital for transporting temperature-sensitive materials. Some tanks are equipped with double walls and insulation layers to maintain the cargo at the desired temperature. Refrigerated tanks, or “reefer tanks,” have built-in cooling systems for transporting perishable goods.

3. Pressure and Vacuum Control: For gases and volatile liquids, maintaining appropriate pressure levels is crucial. Cargo tanks are designed to withstand high pressures, and some have vacuum capabilities to handle low-pressure requirements. Safety features like pressure relief valves and burst discs are included to prevent over-pressurization.

4. Segmentation and Compartmentalization: Larger cargo tanks, especially those on ships, are often segmented into multiple compartments. This design prevents the entire cargo from shifting, which could destabilize the vessel, and allows for the simultaneous transport of different types of cargo.

5. Cleaning and Maintenance Systems: Cargo tanks require regular cleaning to prevent contamination between shipments. Some tanks are equipped with cleaning systems, such as spray balls and high-pressure jets, to ensure thorough sanitation. Regular maintenance and inspection are also critical to comply with safety standards and extend the tank’s service life.

The Role of Technology in Cargo Tank Management

Advancements in technology have significantly enhanced the functionality and efficiency of cargo tanks. Modern cargo tanks are often equipped with sensors and monitoring systems that provide real-time data on temperature, pressure, and the condition of the cargo. This information can be transmitted to a central monitoring system, allowing operators to make informed decisions and respond quickly to any issues.

Automation and remote control technologies also play a vital role in improving safety and efficiency. For instance, automated loading and unloading systems reduce the risk of human error and accelerate the process, while remote monitoring systems enable operators to oversee operations from a safe distance.

Environmental Considerations

Environmental sustainability is an increasingly important consideration in the design and operation of cargo tanks. The transportation of hazardous materials poses significant environmental risks, and measures are in place to mitigate these risks. Double-hulled tanks, for example, provide an extra layer of protection against leaks and spills. Moreover, regulations governing emissions and waste management are becoming stricter, prompting the industry to adopt cleaner and more efficient technologies.

Conclusion

In summary, the purpose of cargo tanks extends far beyond mere containment. These specialized containers are essential for the safe, efficient, and environmentally responsible transport of a vast array of liquids, gases, and bulk materials. From ensuring the quality and safety of the cargo to facilitating seamless logistics operations, cargo tanks play a pivotal role in global trade and commerce. As technology and regulations continue to evolve, the design and functionality of cargo tanks will undoubtedly advance, further enhancing their contribution to the world’s economy.